Shitty jobs

We had a bad smell in the owners cabin for a long time. There are numerous posts on the internet about bad smelling toilets. We read all of them, and always made sure to flush at least three additional times, after the bowl water looked clean. We also used vinegar from time to time. Yet, we ended up with a clocked discharge hose of the toilet in the owners cabin. Of course, I blamed the culprit for eating too much, using a whole roll of toilet paper, not making intermediate flushes and lots of other ‘arguments’ I could think of at the time, which I should not repeat here. Any way, it needed fixing. Some times it is better not be an engineer though.

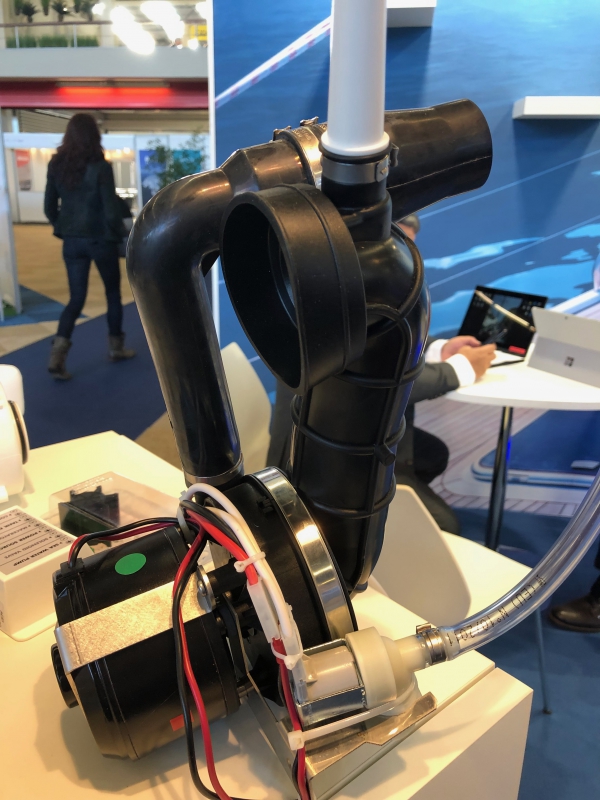

Fortunately, I had studied the design of our toilets at Dusseldorf boat show, so I knew how it was designed. The SFA toilet is actually a very good marine toilet with probably the best, trouble free, macerator. So where does one start to solve the clogging? Well at the beginning….

- I emptied the bowl first. I have a small pump that I can operate with my electric drill. I have a long hose connected to the pump that could reach the opening port near the shower. Adding water and pumping it overboard several times with this pump, made the bowl contents bearable.

- Next step was to disconnect the discharge hose including (!) the non-return valve from the toilet. This way, the discharge stays in the discharge tube.

- Assuming that the macerator was blocked, I took the whole toilet apart. Pfff that is no fun and worse (?) of all, I found no problem. I should have known. SFA has the best macerator……

- The problem then had to be in the discharge hose, which I could not imagine at first. To avoid the contents to drain back, past the non-return valve, I added a piece of plastic with a hose clamp.

- I then removed the complete discharge hose by disconnecting it from the other end and took it through the boat onto the jetty. That went quite easy actually.

- I was shocked by the amount of calcium build-up. The complete hose had at least 2mm thick scales. But that does not block a 2″ (52mm) hose. About one meter from the holding tank, Fountaine Pajot installed a RM69 non-return lip-valve, in addition to the one just near the toilet. Technically very good, even impressive for a production yard. But this non-return valve is sensitive to scaling because of the smaller opening. That is where our problem was.

- I dismantled all the parts. By slamming the two hose sections on the jetty, the scales came loose. We soaked the RM69 non-return valve over night in vinegar, after which it was completely clean.

- The next day, it was time to put it all together again. The good news is, that I noticed that the discharge hose had been leaking very small drops at one of the connections. This explained the bad smell in the owners head. The end of the hose was just not cut square. Easy to solve.

Lessons learned

- The toilet should not smell if installed correctly

- Flushing three more times after the bowl is clean does not stop scaling

- If there is a blockage, it is probably the non-return valve, installed one meter from the Holding tank.

- Using vinegar regularly may slow down the scaling, but will not stop it.

- It is the combination of urine with sea water that cause the scaling

- Flush toilets with fresh water

L&R thx for this nice and pro site.

Just a remark about the RM69 non return valves on the discharge hose.

They are not mentioned in the installation SFA manual.

They are not usefull as they come in double with the one in the macerator wich is of better quality.

Then I removed all of them and changed the hoses 3 years ago and no more issues since.

Btw I clean the hoses with muriatic acid time to time including bottom of the holding tank.