Replacing masthead sheaves

The sheaves in the mast and boom are made from an injection moulded type of white plastic. Over time these will dry out due to UV and break. Two of my boom sheaves were broken already. The pin hole in the centre will wear out over time too, which may stop the sheave from turning. The last thing I want, when crossing oceans, is that a masthead sheave fails. Most likely the halyard will get damaged too. If the halyard breaks in two there is not much you can do. Running a new halyard while sailing is impossible. It is difficult enough in a marina.

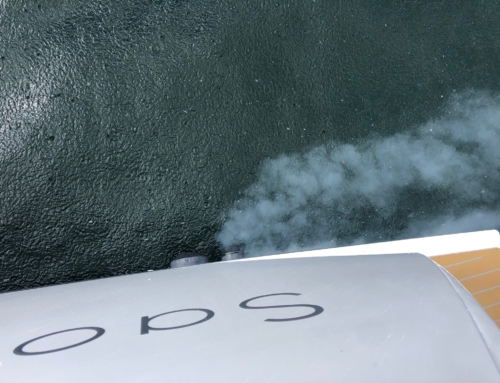

Eight was on the hard in Aruba during hurricane season. That was a good opportunity to replace the mast head sheaves. Zspars suggested to take the whole mast off to replace the sheaves. Renting a man-lift seemed a better option and the price is about the same.

Renting a man-lift in Aruba was quite easy. I was surprised that they did not supply an operator with it. They showed me how it worked and that was it. Ah well, I am allowed to drive a 30 ton truck, so why not.

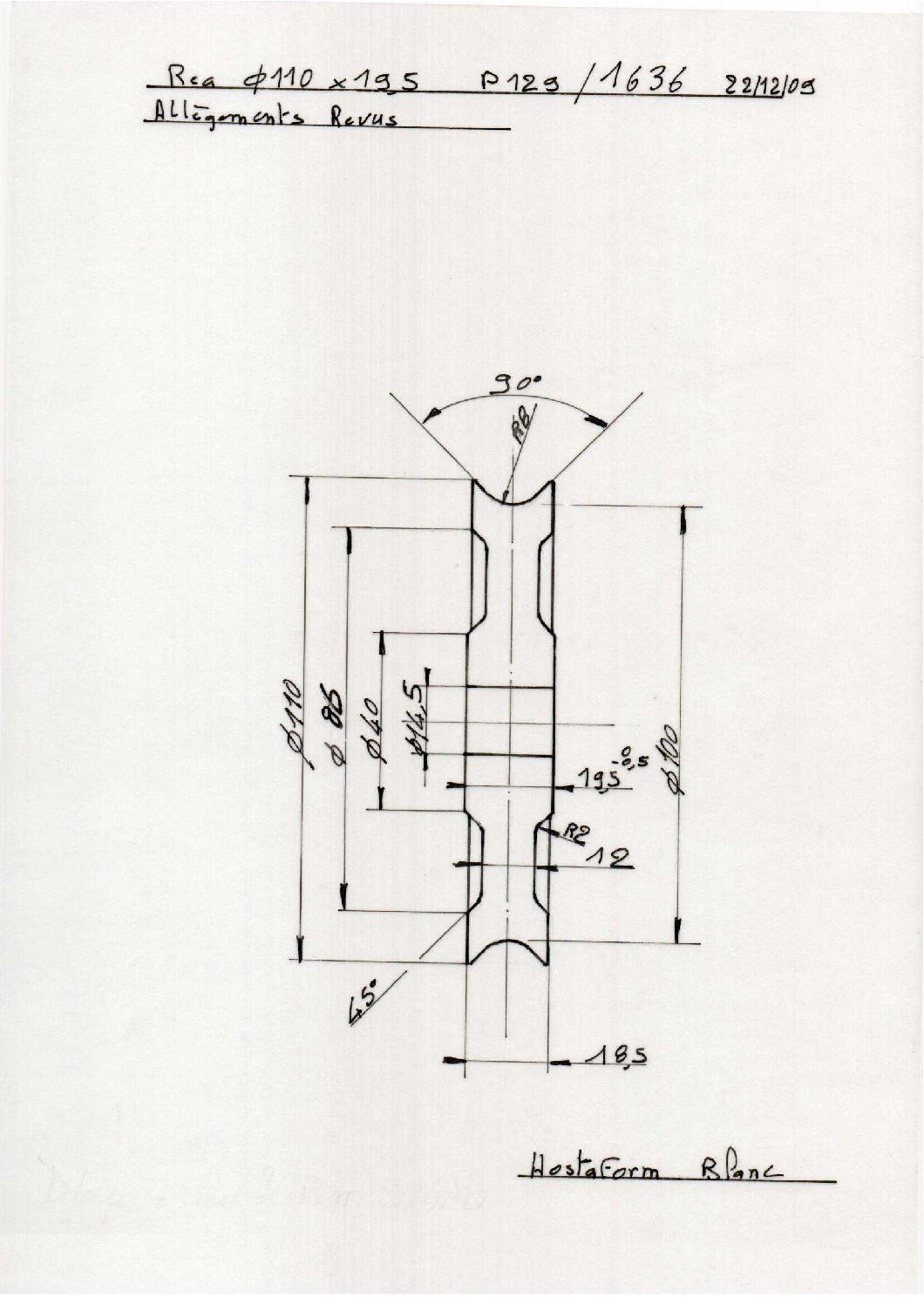

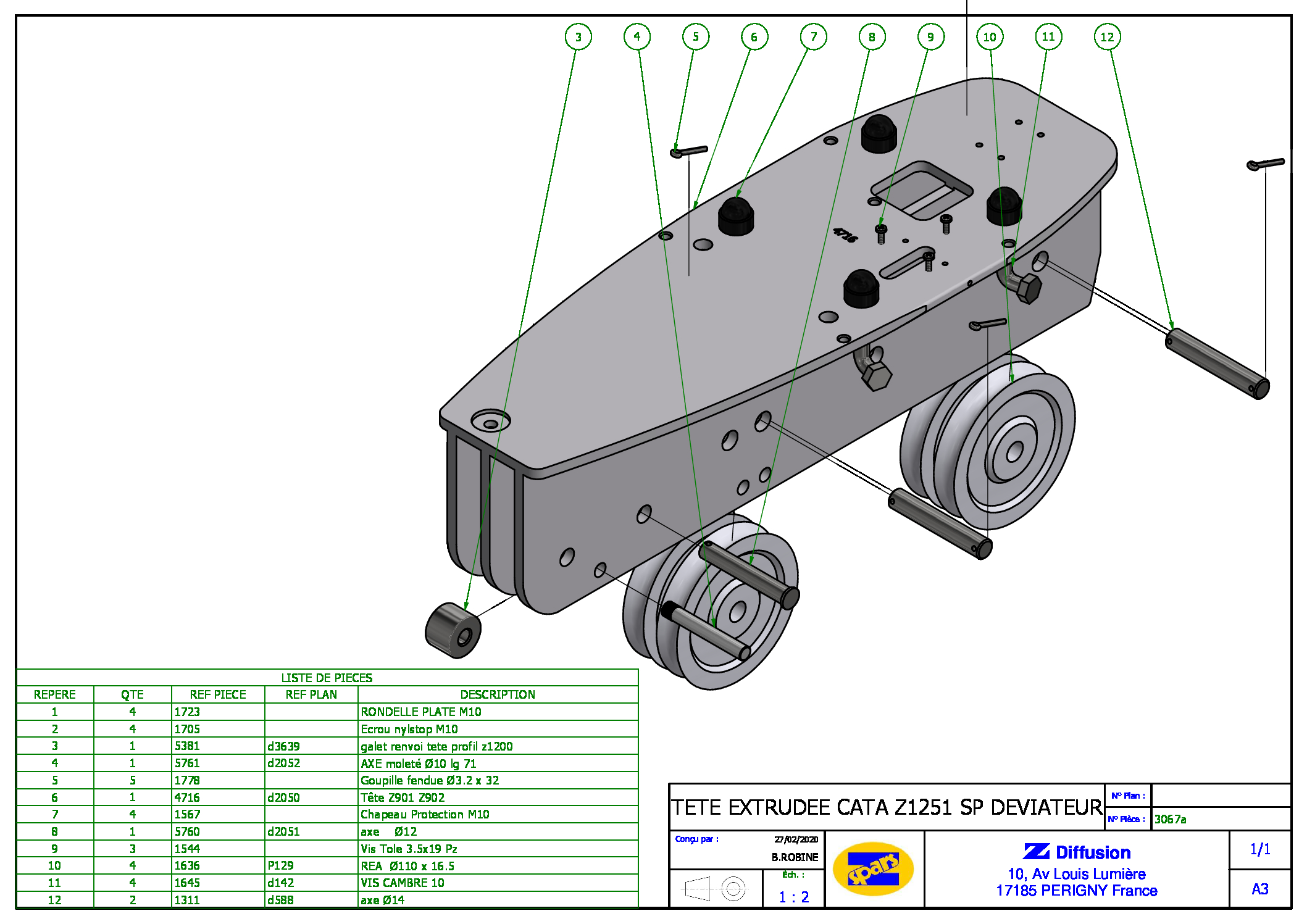

Zspars had provided me drawings of the mast head assembly and of the sheaves. I ordered 4 bronze sheaves from a machine shop in Holland. They are a bit heavy but will last forever. It all looks quite easy if you study the drawing. The mast head assembly is attached to the masthead with 4 bolts. After loosening these, you can move the assembly around a bit to reach the pins that hold the sheaves in place. If the pins are not seized, the whole job may take an hour or so.

I tried to hammer the pins out, but they did not cooperate. WD40 and a bigger hammer (what else) solved it. Don’t hit the pin directly with a hammer as it flattens the pin end. It then will never go out unless you file it round again for which there is not much space. Use a spike or something to hit the centre of the pin only. It took me about 4 hours. It would be so nice if Zspar puts a bit of Tefgel on these pins…

Leave A Comment