Preventing galvanic corrosion

I will try and keep this as simple as possible….

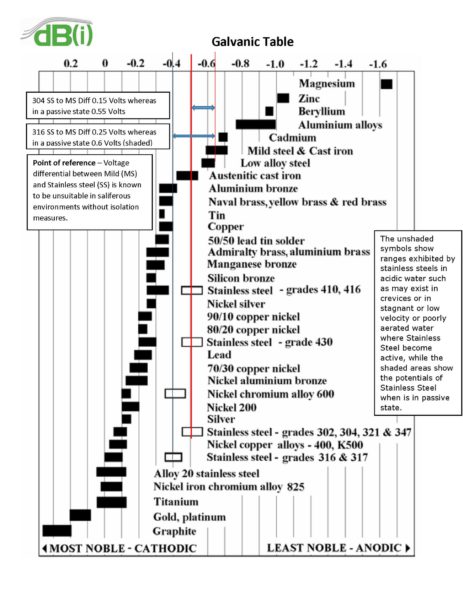

Two dissimilar metals in a conductive liquid create a sort of battery. This means that the less noble (weaker) of the two metals will dissolve in favour of the more noble metal if the two are connected. We call this galvanic corrosion. It works just like a normal battery. If you connect a light between the two poles of a battery, a current will flow and the light goes on. Without the light connected, nothing happens.

Seawater is conductive. Two connected metals submerged in seawater, not only form a battery but the current can flow too. A good example is a bronze propeller on a stainless steel shaft. If you do nothing, the propeller will dissolve. To avoid this we install sacrificial anodes. This is an even weaker material than the bronze propeller so it will dissolve before the propeller does. Note that this only works if the anode is connected to the item you want to protect. In seawater we use anodes made of zinc. Check your zincs regularly if you want to keep your propellers and saildrives healthy.

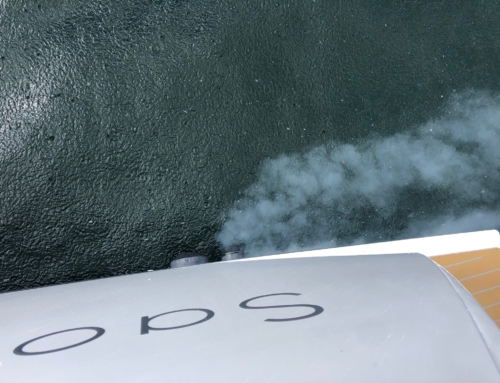

Under water this is taken care off . Above water it is not and this creates problems. Imagine an aluminium item fastened with stainless steel bolts, such as your steering housing. See picture. When salt water enters between the bolt and the steering housing, you have two dissimilar connected metals in a conductive liquid. The alumium will dissolve. Over time you will see a grey/white salt deposit develop. This should ring an alarm bell! It is impossible to prevent the seawater to enter between the bolt and the aluminium housing. There is no way we can fit a zinc between the bolt and the housing. So the only option we have is to make sure there is no direct contact between the stainless steel bolt and the aluminium housing. remember: if there is no connection, a current cannot flow.

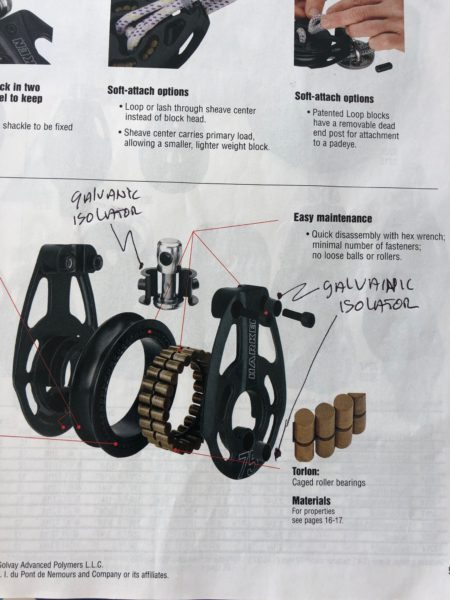

On high quality equipment such as the Harken block in the picture below, there is a plastic insulator between the bolt and the aluminium block. Our steering housing does not have this. But there is something you can do to disconnect the two metals. Use a product such as Tefgel (developed for the Aeronautic industry) or Duralac. One of the first things I did on our boat is loosen the steering housing bolts, added Tefgel and tightened the bolts again. I prefer Tefgel because it does not dry out in the tube it comes in. Duralac is a bit messy to work with and it dries out. But also locks the bolts like LockTite, so it has its advantages. I have both on board.

Leave A Comment