Lots of work done and still to be done @EIGHT! Instead of having fewer jobs it looks like there are more and more jobs to do! And some complicated jobs as well! The list may inspire you. But the thing with all boatjobs is, that it all takes a lot of time. Once you start a job you’ll find that you are missing a bolt, screw or fitting to complete the job and all shops are closed … ok, next job. Same problem. Next day you go and buy all the missing parts and continu. Somehow you never finish a boat job in one go. Every boatjob takes a lot of time! To be honest we are sort of over organised but we like that. Since we left Holland it is more diffficult to get things done. One thing you definetly learn: make choices! Shall I bring this on board, do I really need this …. and so on. But we are enjoying Eight to the max! Good luck with your boatjobs!!

This is the list what Robbert did so far…

Hull – Deck – Cockpit

- Underwater Lights

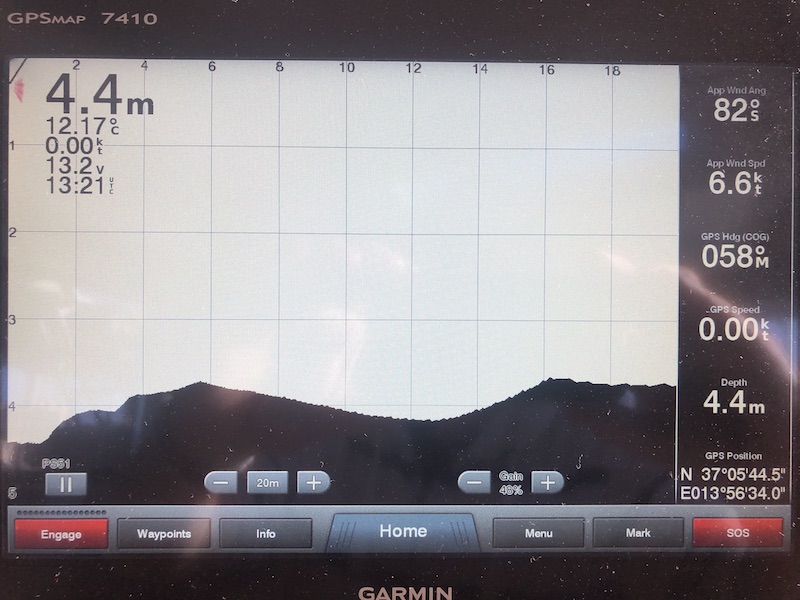

- Forward-looking depth sounder Panoptix by Garmin

- Eight logos on 2 sides on the bow

- Homeport sticker on the transom

- Added shock absorbers on the bridle

- Step fenders @transom including splicing fender lines and installing pad eyes. It doubles as a rear end fender. We do not like the FP optional bumper

- Flag and flagpost. Note: height of flag ‘should’ be 6% of boat length … so about 80 cm. high and 120 cm. long

- Flagpost holder on upper deck

- Fishing rod holders

- Fender socks over existing fenders to avoid scratches on the hull

- Three gas bottles and reducer

- Sika teak deck in the cockpit. A new development by Sika using a polyurethane. Lasts twice as long as the standard PVC

- Fit carbon steering wheel. It was a present from my sail racing buddies

- Install passerelle deck cup

- Anti-drip strip near helm station. Our stern is still light without tender. So the boat tilts forward when water tank is full. Rainwater than drips down at the wrong place

- Lash scuba tanks on deck

- Cover plate over aft locker drain to keep locker dry

- Seal off bottom hatch in central cockpit locker to keep water out

- Made accessories storage at helm station for horn, binoculars, bearing compass, iPad, sunglasses etc.

- Davits modification. Added padeyes and changed the purchase to 1:1

- Single line hoist system for tender.

- Storage brackets for electric scooters in SB engine compartment

- Added 230 volt socket plug in cockpit for various appliences.

- Sun awning above bunny deck

SAFETY

- Jacklines

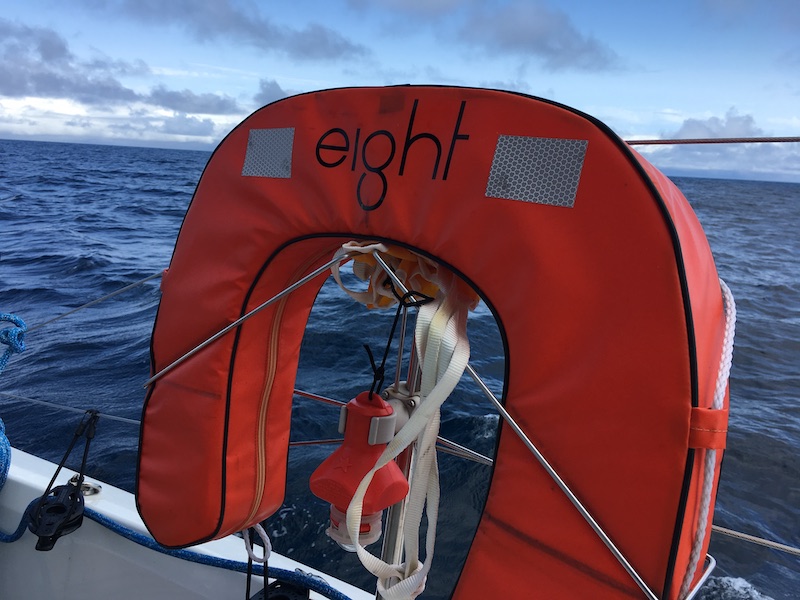

- Horseshoe buoy with light and droque

- Life sling

- Jon buoy

- Deck cups for emergency tiller. The standard tiller can only be used when engine room hatch is open. I don’t like that

- Life raft frame on the transom and fit life raft

- Fire extinguishers: one 2 litre foam in each cabin. One 6 litre foam in salon. One 2 litre powder in cockpit seat

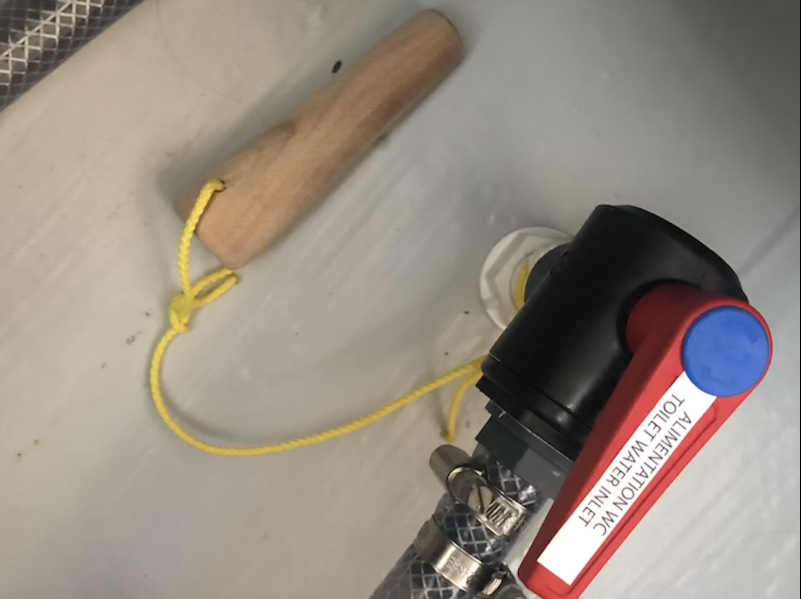

- Wooden plugs near seacocks

- Fire blanket in galley

- Grab bag

- Pyrotechnics – emergency flares

- First aid kits

- Install personal Emergency beacons on life jackets

- replaced white compass bezel by black bezel to reduce light off the compass

- Install Iperb

- Garmin In Reach

Mast & rigging

- Lead tack line to helm station, including fairleads, padeyes and jammer

- Make preventers on main

- Outer jib sheets

- Anti-chafe strips for outer jib sheets

- Replace spinnaker halyard. The splice of the existing halyard jammed in the mast fitting

- Mainsail head connection line, just so that you do not need to attach the head to the car manually. Investigate Karver hook ….

- Additional jammers and pad-eyes for tack lines on bows

- Additional bails and foot-blocks on bast base

- Replaced single foot-blocks by double foot-blocks

- Crossover block aft of jammers lead halyards and reef lines to other winches

- Install 3 jammers near central pit winch

- Replace inboard end reef straps for reef #2 and #3 by line to new jammers. I do not want to climb the mast to put reefs in

- lead spinnaker halyard to pit winch so it can be operated from the pit

- Jammer for jib sheets, so that you can transfer the sheet to another winch and foot-block with locker

- Put gennaker in snuffer (sock)

- Improve gennaker sheet lead to davit winch on port side aft.

- Additional pad eyes and ratchet block to make pulling the snuffer (sock) much easier

- Install code zero furler, including line, fairleads and deflector blocks

- Install screecher sail on code zero fuller

- Replace main halyard

- Tension all bolts and nuts you can reach

- Remove 1 ball from each ball bearing race from mainsail bat-cars. Else they do not work properly

- Drilled holes every 50 cm and inserted Sika in the tubes around the stay to stop the rattling by wind.

- Added extra standup blocks and jammers so I can sail with a symmetrical spinnaker

- Cut off spreader bolts and taped all

- Spreader chafe patches on mainsail for protection

- Radar reflector

- Mast steps in top of the mast. Easy when working on masthead

- Prepare bosun chair

- install shock cord between upper spreaders and shrouds so that spinnaker does not catch behind spreader

- Add nylon sheave protection on the upper forward spreader. My spinnaker got stuck on upper spreader

- Halyard to lower jib on board

- Spare lines for all lines on board

- Single line hoist for tender

- Replaced traveller by Harken traveller

- Replaced traveller line footblock by Harken footblock

Electrical

- Added 2 batteries and cables. Lithium is on the list for the future

- Three more solar panels, 165 Watt each, on the upper deck

- Air pump to inflate SUP’s, fenders, tenders

- Update Victron battery charger characteristics to charge at 80 amp. Possible, now that we have 6 batteries

- Added a second Victron charger of 80 amps for quicker charging.

- Make splash cover for generator inverter. We had some sea water ingress in the generator inverter. I think it comes through the vertical stainless supports of the traveler beam, which is hollow

- Install a diesel driven hot water generator and replace the boiler. Very difficult to do …

- Installation of dive compressor

- Install soft start for dive compressor

- Install Watt&Sea generator

- Install T-valve on water maker outlet hose to drain/check fresh water

- 12-volt distribution box in helm console

- Install UPS charger near helm station

- Added 230 volt 190 liter/hr water maker in addition to the 12 volt 60 liter/hr. Target is to run genny max one hour per day and fill tanks.

Electronics

- Plotter at helm station We ordered just one in the NAV station

- Install an electronic navigation chart

- Enter MMSI and call sign number in VHF

- Install Active Captain software

- Yacht devices NMEA transmitter installed to have Garmin data on iPad and computer

- Install mobile printer

- I-pad holder at helm station

Winches

- 4 Electrical Harken rewind winches. These pull and ease the line electrically

- 350 Meters of electrical wiring to control all winches from nav station, helm station and foot switches

- Winch control panel with 8 push buttons at helm stationed nav station

- Foot control switches for Harken halyard and jib winches

- Add foot-switch for mainsheet winch and davits winch

Anchor locker

- Anchor chain, gypsy, and anchor. We changed to 10 mm high-grade chain and 33 kg Rocna anchor

- Freshwater deck wash pump

- Install Blue Performance accessories bag in anchor/chain locker to store bits and pieces

- Brackets in anchor locker to hang spare sheets, halyards and mooring lines

- Brackets to store gangway/passerelle

- Anchor windlass control with chain counter in the chain locker. Standard one comes without chain counter

- Make cover plate over anchor chain opening to prevent water in the anchor locker

- Make fairleads for Mooring bridle. I don’t like to run th elines outside of the bow as these get damaged. Over the beam, as it is, the lines wear through in a day

Saloon

- Carry loads of boxes of wine!

- Extra clothes hooks in owners cabin

- Install clock, barometer, hygrometer, and thermometer on mast post

- Modify saloon table and install in the saloon

- Sliding mechanism for salon table for ease of seating

- 4G Wifi for now

- Add extra sockets in the galley, saloon, guest cabins, and starboard peak

- Dimmers on LED lights in saloon. Current lights are too bright

- Clean shower shelf guard in owners cabin and add nylon washers so dirt does not get rapped any more

- Shelves in port and starboard peak for additional storage

- Made removable bars in starboard storage shelves to keep storage boxes in place

- Make a cover for cockpit table

- Make a cover for the spare anchor

- Make a cover for passerelle

- Extra shelves in cupboards of the saloon

- Make repairs with Sailrite on cockpit tent due to 12 BFT storm ….. Fun job though!

- Clean all cushions at home

- Make throw cushions for cockpit

General

- Fuel funnel with strainer and water separator

- Basic spares as winch grease, pawl oil, Sika kit, was, cleaner, buckets, filters etc

- Replace fuel filters

Still to do list

- Install camera to see port aft section of the boat

- Beamer for cockpit cinema

- Continuous improvements

- Fixing wear and tear

- Drink more wine and relax

SPARES SPARES SPARES!!!!

EAT, SLEEP, WORK, REPEAT??

Working on the pictures of how and where things are installed!!

If you like to keep up to date with our stories, technical updates please subscribe to our newsletter. And don’t worry we won’t spam you every week! No time for that: too many boatjobs @8!

Hallo Verboontjes,

Gefelliciteerd met “Elegant” Eight! Bizar hoe lang de lijst met werkzaamheden kan zijn op een nieuw schip. Ik wens jullie heel veel veilige en vooral plezierige mijlen toe en hoop jullie een keer op het water te treffen.

Groeten,

Hans Jonker

Hallo Hans,

Dank je wel voor je bericht! Je moet ook wel wat te doen hebben Hans! …. En het is ook Robbert zijn hobby.

Het zou leuk als we mekaar eens treffen! Je kan ons volgen, dus als je in de buurt dan horen we het graag!

Groeten Luuke & Robbert

Imposante lijst modificaties en aanvullingen ! Allen zeker de inspanning waard !

Safe travels !

Gijs en Lotte

Hans,

Thank you so much for taking the time to post your list of improvements. I am in the process of purchasing a FP47 and this list will be very helpful.

Happy Sailing!

Doug Patterson

Santa Cruz, CA

Wat fantastisch wat jullie doen! Maar waarom hebben jullie mij niet meegenomen als onbezoldigd manusje van alles. Ik kan koken, stofzuigen, zeilen, en nog veel meer. Heb zelf nog een uitnodiging staan om van Bonaire naar Tahite mee te varen met een Engels-amerikaans echtpaar maar ze zuipen me teveel. Jammer voor jullie dat ik er niet bij ben.

Maar geweldig wat jullie doen, helemaal super.

Hello Hans.

I am working on ordering a Saona 47 with delivery date in May next Year. Your list is very much appreciated and super helpful. I am just curious to know if FP took some of your topics for quality improvement.

Did you got any feedback from FP on all this repairs and modifications ? I saw your video where you had to fix 2 times the engine starter unit. What is FP thought on that ?

Hi Frank,

There are several things that FP changed based on my feedback. Not all are covered by posts though.

Note that engine MDI box problems are a Volvo problem and not an FP problem. It looks like that the latest MDI box design is ok. I have not seen complaints recently, but then nit everybody shares their problems online.

The Saona is still our favourite boat in the market today.

Robbert

Robbert,

We bought a new 51, delivery July 2022. We like the improvements you made to Saonna 47 and most likely follow suit on most where applicable.

some questions.

A. Is there a small outfit near the factory that we can hand this joblist and pre-ordered equipment? Or even better have some wiring already installed at yard befor assembly process?

B. Are you happy with Harman electronics, I am more a B&G guy?

C. Would you consider the Karver hook, furler or even some winches in the end?

Don’t wanna ask to many questions when you are not sipping away on a G&T in Caribbean. No offence if reply looks like a old telex?

I am a Dutch guy as well, sailed mega yachts in 90 ties, Korean wife and Son Max, we have lovely friends with whom we bought boat and go cruising in Med and Carib for a start and later make more plans…..

Talk soonwe already follow you guys. Enjoy your inspiring trip!

Hi Patrick,

The yard will not make any changes. That is the only way to keep production costs down. My experience with my boat is that there are plenty of empty ducts and tubing to add cables later. There are some local companies but experience of boat owners with them varies. Guess it depends which of their employees are doing the work. They have been overloaded with work the last few years. it is hard to find experienced and dedicated workers.

The best I can suggest with a new boat is to spend some time near La Rochelle for a few weeks to test and check-double check everything on board. Also concentrate on small gell-coat imperfections which every boat has when it comes out of the mould. In La Rochelle, the yard can arrange to solve issues quickly. Once underway it becomes more difficult. For installation work I have good experience with the dealer in Holland. Thijmen is not a ‘sales-type’ of person but a knowledgeable technical guy who does all installations very nicely. I know it is a detour but it will be worth it.

Hello Hans,

Great website with many interesting modifications. Can you do a write up on your SCUBA air compressor and tank mount system. I have a Lucia 40 and want to install both on my boat. Keep up the great work/fun.

Cheers,

Steve

I installed a horizontal platform aft of the engine. The compressor is not fixed onto the platform. On a cat it just stays where it is. It juts has a small edge that keeps it in place. I need to tilt my compressor slightly forward to remove the air filter. That is why the installation is as it is. But for a different compressor, other requirements may have to taken into account. I had to remove the air filter and muffler from the engine to place the compressor.

My compressor has an electric control box with an on/off switch. I extended the wires and transferred the switch to a place which is easier to reach. For that I converted a Plastimo water fitting. This has the switch but also the quick connector for the hose.

Thank you for this. So many great ideas I’ve gotten from your work. Thank you.

Love the mods especially the re-wind winches and controls at helm and nav station, would be one of the first mods along with the higher capacity batteries and chargers