Watt and Sea

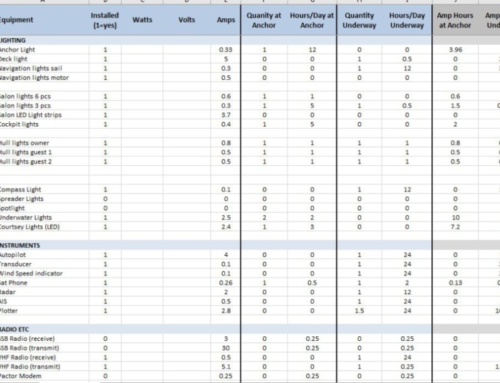

I have 840 watts of solar. During sunny days and about six hours per day, that will generate enough energy to keep the boat going and the wine cold. When we are on autopilot we use about 20 amps or 480 watts /24 hours per day. Obviously that is more than the solar panels generate. I therefore decided to install a Watt and Sea Hydrogenerator.

Problem solving

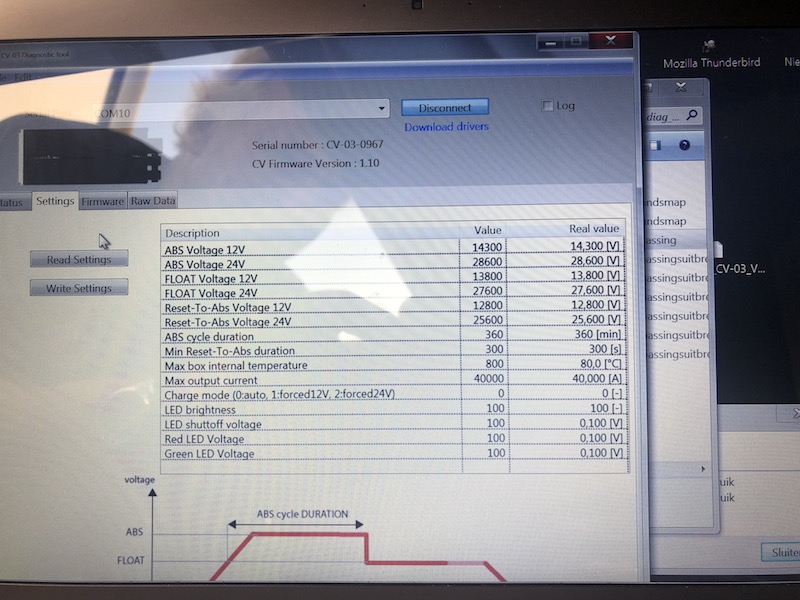

I followed the installation instructions. When we first tested the unit it was generating 25 amps (300 wats) quite easily. When I took the unit out of the water, I noticed that the shaft seal was pushing against the propeller (impeller actually) and created a lot of friction. I was already happy with the 25 amps. Without the friction it would be much more, so I thought. So the unit went back to Watt and Sea for repairs. It came back a few weeks later. Put it back in place and tested it. The best I got out of it was 10 amps or so. Very disappointing, knowing it had done better on day 1. Discussed it with the distributor in Holland. After many calls and emails via them to Watt and Sea they decided finally to let me talk to the engineers of Watt and Sea directly. Their first conclusion was that I did not install it properly, that the cable was damaged etc etc. blah blah blah. Well, sometimes it is great to be an engineer. I had measured the resistance in the cable and that was normal. They still did not really believe me but o.k.. They sent me a procedure to test if the Watt and Sea unit was working on all three phases. It was. The only thing left to check., was the inverter that comes with the Watt and Sea unit. Watt and Sea suggested to add an Amp meter directly on the unit so that I could see that it was working perfectly and that the problem must be in the boat somewhere. I asked them if they did not have a Victron inverter, because that comes with a bluetooth transmitter showing voltage and amps. But the Watt and Sea unit is three phase so not possible. But…..(this was after two months) they told me that the inverter had a built-in monitoring system. But it was very difficult to read the data. What do you mean difficult? Well, you need a micro USB cable, and a laptop and drivers…Hey, I am an engineer! So 15 minutes later everything was hooked up and data showing on the laptop. I put an electric drill on the prop shaft to get some RPM. Recorded all the data and forwarded it to Watt and Sea. It was showing clearly that the inverter had no output. But they noticed also, that the input was not o.k. So the Watt and Sea unit had to be sent back to the factory for the second time. It appeared that when they did the repair, one of the magnets was installed the wrong way around. They really felt embarrassed. Problem solved.

Field test

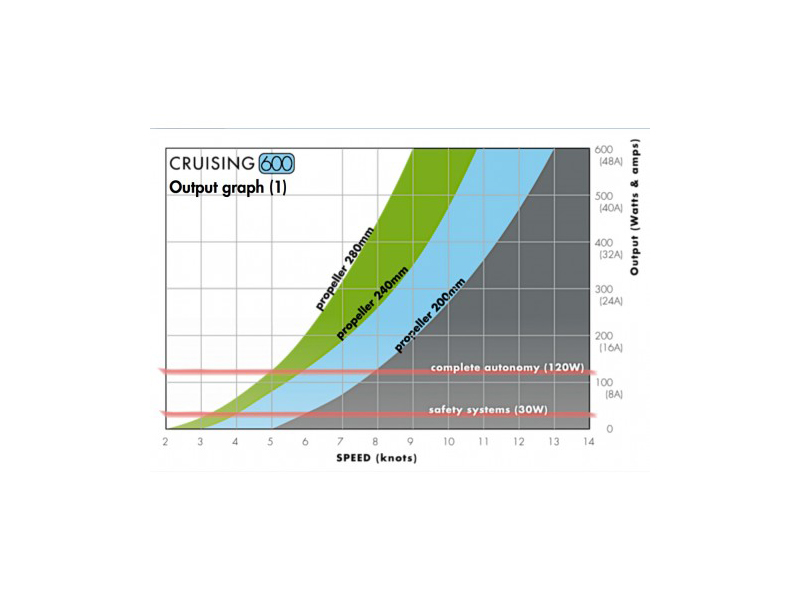

Testing is not that easy actually. Preferably you do not want any other piece of equipment charging the batteries. With solar and or engines running that is a problem. Also you do not want a full battery, else the inverter will reduce the charge current. Over the winter we did not get a chance to sail much so testing took a while. But when we finally did, the unit produced the exact amps according to the data sheet. This is quite impressive. 400-500 watt is a lot of energy.

Lessons learned from testing

I have three different prop sizes so that I can select the prop size based on boat speed. The largest prop does not want to see much more than 9 knots. If it does, the inverter shuts down the unit to prevent damage. By doing so it gets hot. When it gets hot it shuts down all together. So pushing the unit at higher speeds delivers very little energy due to the shut off. I was getting the best output with the standard 240mm propeller. As of 6.5 knots of boat speed I have about 20 amps, which runs the boat.

The largest propeller was suffering from ventilation at speeds around 9 knots and up. That is not good for the efficiency either. Some propeller knowledge for you: Ventilating means it is sucking air from the surface. Cavitating means that due to the low pressure around the suction side of a propeller, the water starts boiling (yes, at low temperatures) and creating bubbles that implode. The imploding bubbles create vibrations and can cut right through the propeller blade like a hot knife through butter. The solution is to install the unit lower in the water.

Lifting and lowering of the unit is done by two control lines. But the load on these lines is enormous. It cannot be done by hand and requires a 3:1 purchase. I could not find a nice way of applying the purchase.

Improvements

Installing the unit lower, meant drilling new holes for the two brackets. That would still not solve the force needed to deploy the unit. So I installed a Harken track with two cars and mounted the unit on the cars. No one has done this before, so it was a bit of a gamble, but it works perfect. Watt and Sea is now offering this option to their customers. I can lift and lower the unit with one hand. I can still swivel the blade upward like a dinghy rudder, to replace the props. It was a bit of a hassle, but in the end I am perfectly happy with it. Because I have no platform, I have the most perfect spot for installation. Out of the wake and reachable. In hind sight, I should have installed it on the port side to have shorter cable runs, and install my life raft on starboard. The life raft cradle did not allow this, but I converted the cradle because I did not like the way it worked. With the modification I could have installed on starboard side.

Parts used for the track and cars:

2 x Harken Cars #2726. 227 kg SWL

1 x Harken track # 2720.1.2m cut to length

1 set endstops #173

2 stainless steel plates 70mmx50mmx5mm. Holes to match car and standard Watt@Sea brackets.

1 x Harken #150 cleat for line.

Update

After using the Watt and Sea a lot I noticed that it shuts off way too often due to overheating. The Watt and Sea inverter is installed in my port engine room. The hot water boiler is there too. Also the Flexiteak on the engine room lid, absorbs lots of heat. On normal days the engine room temperature is already 40 degrees without using the engine. I talked to Watt and Sea how we could cool the inverter so that I have more energy. They sent me an extra housing. The housing is an extrusion. Electronics are sealed inside. The extra housing is bolted back to back to the original unit. This increases the cooling surface enormously. I also added an active ventilator. It does mean the electronics are no longer sealed but I generate twice as much energy now as before. On our ARC Atlantic crossing, I non-stop used the largest available propeller. We reached a top spreed surfing down a wave of 17 knots. The unit never overheated.

I really like your setup Robbert and Luuke. It’s amazing how you installed the Harken rail system!

Goodmorning Fred,

Thank you for the compliment! If you have any questions please ask!

Friendly regards, Luuke

Hello i am about to do the same on an Astrea 42, thank you for the work you share.

I hope i will have less issue with watt and sea.

Did you buy the short (610 mm) of the long (970mm) mast ?

Thanks

Hi Lionel

We bought the long one, as I had it installed the tradional way. Then I added the track but then it could not be raised enough so I shortened it by 15 cm. Now I want to shorten it another 10 cm.

Quite easy to do. Make sure to install it at least 15 cm lower than advised.

Order the unit with a double housing for extra cooling.

I can now use the bigger prop non stop.

Robbert

Hello

I am on your track for the installation of the watt and sea Hydrogenerator (but several year behind and currently blocked by the covid19)

I will use the rail set up you designed, but I was wondering which type (sise and material) of backing plate you placed to secure the rail

Watt and sea says that the load could be up to 350 kg.

Take care

Hi Lionel,

The Harken Hi-Load Small boat cars have a Safe Working Load of 385 kg. The Track is fitten with M5 bolts every 10 cm. Of course the SWL of the Track corresponds with te car. I just fixed the Track with M5 bolts and washers/nuts behind it. The installation place on the Saona is that of the Hydraulic platform. That is a very stong bit of lamination. No problem at all.

I am very interested in how you hooked up your computer to the Watt and Sea. Can you share the driver/software? My unit may be too old to be compatible — it’s the original 500W version — but it would be nice to learn more about what is happening. Thanks!

Hi Harry,

The inverter has a white plastic lid. You need to take that off. Then you will see a connection for a micro USB.

I will email you the driver software.

Hi! I recently installed the Cruising 600 with a similar track, Antal automatic usually used for halyards. All fine except the outcome of the watt and sea. Very disappointing. Wanted to analyse before I come back to the W&S guys.

I checked several time on our last 3 day offshore cruising with the iPhone app, analysed the data now. The W&S never revved up to more than 1200 rpm, producing never more than 8 Amps @24 volts.

We did upwind btw. 5-9 knots on a Dykstra 55 and had the 240 mmm prop.

What is your normal relation regarding revs to output ? Would you send me the control software.

Thanks Robert

Hi Ron,

My W&S actually produces the exact amount of energy as per their power graphs.

8 Amps@24 volt is about 200 watts.

With the 240mm prop you should get between 90 watt (5 knots) and 350 (9 knots) watt.

In my case the Watt and Sea is installed between the two hulls in free flow of water. In a mono hull it will be in the wake of the boat where the water speed is considerably less. For the relationship between rpm and produced energy I would contact your watt and sea dealer. I don’t have those numbers.

Are the leds on the converter pinkish to white or do you see red/green flashes. Note that if your battery is full, it will reduce the charge current.

Robbert

Thank you ! I sent the log files to W&S and wait for their analysis. I have not looked at the LEDs. The battery was never full, I had to run the engine once in 4 days as the AP was running all the time and the gen could produce enough energy.

Fair winds, Robert

I am interested in their reply. Let me know.

Robbert

Hi again

What was the reason for not installing at the end of the hull/swim platform? I didn’t understand what you meant by ” I have no platform”.

Thanks for putting up Tech Stuff, it’s very helpful

AL

We did not order the dinghy platform for several reasons. So that provided the option to install the W&S to the hull directly. Leaves the end of the hull as an installation option. The problem is that you need a 4:1 purchase to pull down the blade and even then it is hard work. With all the sargassum grass, we often need to raise and lower the blade several times per day. The only place to attach the 4:1 purchase to is the overhang behind the traveller. Not a very nice option, but could be done I guess. Having the flat platform installation section on the hull, allowed me to put the W&S on a track. No Purchase, I can operate it with one hand, even at high speeds. I can also still tilt the blade to replace a propeller.

Hi

I’ve just installed a cruising 600 unit and am curious as to how much effort should be needed to turn the prop as it seems a little stiff to me but the instructions are not very specific. To be clear the unit has not been in the water yet so it may be fine.

Thanks

It’s normal that there is a bit of friction!