Upgrading traveler

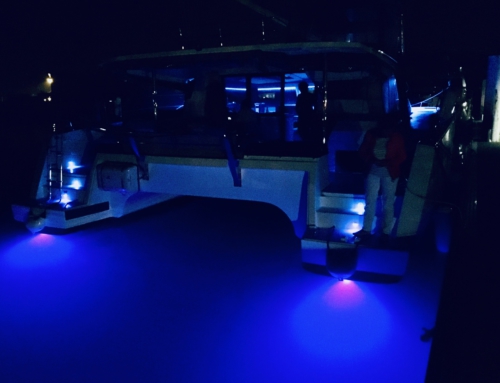

Some jobs are a great addition, other jobs make no sense at all. As one of the largest Harken distributors in the world I cannot sail with a poor functioning Lewmar traveler. Two shorter cars have less friction than one long car.

If Z-spars would have drilled the bolt holes a bit more accurate, it would have been half a days job. Now it was a full day with lots of f#%*$¥£. Any way, I have a cool traveller now where the main sheet blocks cannot catch behind one another. The damage on the Harken blocks were caused when using them on the Lewmar traveler that you see in the pictures too. Those blocks are too close together on the Lewmar car and catch behind one another. This damages not only the blocks, but can also damage your main sheet and it causes lots of friction. I also reduced the traveller line purchase from 3:1 to 2:1. I have a strong electric winch for the mainsheet and traveller lines, so I do not need the extra purchase. I can control the traveller car faster now, with less friction.

If you can live with the Lewmar traveler, just leave it. Lewmar end controls are very flimsy I noticed. Lots of bent bolts eating away the alloy. Use lots of Tefgel when you install stainless bolts in aluminium.

Parts used:

- R32.6M harken track

- 40 x Allan key Flathead bolts M8x40

- 2 x T3203B Harken traveller cars

- 1 set 3173 Harken end controls

Tools used:

- Allan keys

- Spanners

I really like the content you post on this site, keep up the good work.